Making My Own PCBs

I can certainly say that over the years electronics has changed a lot. For example, in the late 80’s when I started making my own hobby projects it was all through hole leaded parts and using strip board, plastic boxes (even recycled ice-cream tubs) and scrapped electronics boards out of VCR’s etc to build some crazy idea you had. Far too many years later and a career of designing electronics products later I wanted to get back to that original hobby way of working and making projects at home. The problem is not only have the parts become surface mount, a lot smaller but my eyesight is far from what it was. So, I asked myself, how do you go about making hobby electronics today and on a budget?

One thing for time having past is that not only have I learned a lot more but the tools like schematic capture and layout are a massive leap forward from what I had back then. I picked up KiCAD as the go to tool when it comes to hobby electronics despite using Altium in my day job, KiCAD is free, powerful and full of support from the online community. Certainly, when I stared out with Cadstar or EasyPCB there was a user guide, and you got on with it. So, it seemed perfectly reasonably to use a free tool for hobby electronics.

In order to test out how to make a hobby electronic boards I decided to start with something very simple. A microcontroller, onboard regulator and a few connectors for access to a UART, I2C and analogue input etc. I have in the past used Microchip parts but also been a fan of the mbed boards based on the ARM core. So, when looking around I came across Phils Lab, a design engineer who has some really good guides on designing electronics but also a video on using KiCAD. His guide / design uses a STM32 part that also has an ARM core and so that basically that made my mind up and I followed along.

As I said at the start the big challenge for me is getting a PCB made and fitting the small parts at home. I know people used to use acid chemicals and UV light to etch PCBs at home but that’s horrible stuff. However, the trend is to use online rapid PCB manufactures like JLC and PCBway. I certainly remember this idea starting off around 10 years ago when you could use PCBtrain in the UK to get cheap PCBs. The video I was following along with used JLC but I had heard a number of people recommend PCBway. I also saw that Phils Lab in later video was also sponsored by PCBway. So, I decided that I would opt for PCBway – its good enough for him after all.

When designing a board with small parts under 0603 you really start to struggle to solder them without good equipment. The STM32, the Crystal and the USB connector have very small 0.5mm pitch or pins you just cannot access. So, there was no way I was fitting them, therefore I basically had to choose having a PCB made and parts fitted.

I was well impressed with the results having the boards delivered in a few weeks at a good price too. OK a little more than you may pay for a round of drinks or a meal out, but I guess electronics as a hobby has never been super cheap.!? I received 5 off boards and all were perfect. But I then wondered if I could get the cost of making my own boards even cheaper?

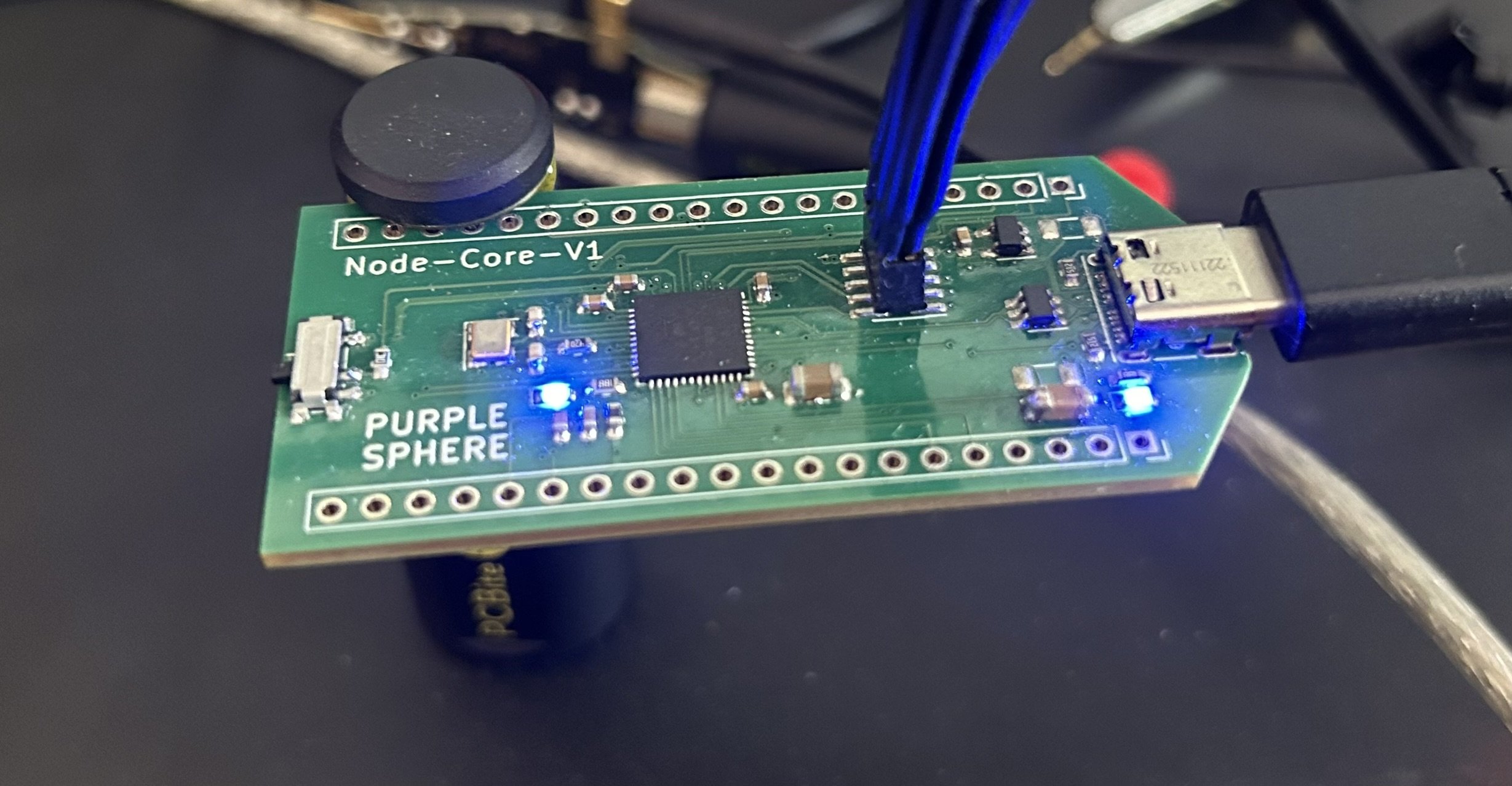

The next project I started on was again using the same main parts including the STM32, this time using a USB-C connector and with strip pins along the side so I can plug it into a bread board. This time I decided that I would have a go at placing the parts by hand, but not solder them instead I would try out using a stencil and solder paste along with a hot plate.

Having sent off my design and finding that cost was down around 33% I ordered the parts I needed from DigiKey and waited for them to arrive. In all along with parts I was still saving money and in my mind, I only had to fit parts to the boards I wanted to. You get a minimum of 5 PCB from PCBway and I could just build 1 or 2 if I wanted and keep the parts for another project.

I also obtained the MHP-50 from PCBway. It’s a small 50mm x 50mm hot plate for reflow work and about the same size of the board I had on order. It also has a nice feature of an added reflow profile. This allows you to ramp the temperature up and follow the same profiles the big SMT manufactures use.

With everything in hand, I tried applying solder paste! Let me tell you it’s not that easy! I tried a few methods of sticking the stencil in place and using scrap boards to support it etc. Any search on YouTube will show you people banging out good results. I think I went through a number of boards before it stopped smudging and getting a constant covering. Then come placing the parts and with the help of a USB microscope I also made just as bad a job of placing them. When I tried the reflow, I ended up with solder shorts or bad joints. It took a while, but I found the MHP-50 has a temperature sensor under the hot plate that was not making contact, and the hot plate was way over temperature.!

Having fixed the hot plate my placement of parts was improving. Thankfully I had this time picked larger parts to place but personally found getting the STM32 aligned on its pads the hardest part. With lots of experimentation, I did finally get a working board but at the expense of a few dead STM32’s and a few burnt PCBs.

The few that I got working all worked well and I can’t be critical of PCBway with the quality of the PCBs or the stencil as it was just down to my abilities. I did then spend some time looking at how to apply solder paste better and some basic tools for placing parts however I felt this was going beyond my budget for a hobby?

I decided to reorder the boards but this time with PCBway doing the assembly. These arrived and worked perfect however I did get hit by an import duty for customs. I guess I hit some limit on the cost but will be looking at this in more detail next time as was certainly an unexpected cost.

So how hard is it to make electronics now? Well, I found KiCAD very good and using someone like PCBway to make your boards was also a good experience. I feel I lost the experience of the whole “building it yourself” is lost when you work this way, but I guess that’s how the world has changed? I would like to find someone that can make a single PCB populated with parts even if you get a few extra blanks as having five made puts the price up I feel. I understand that the company has to have a minimum spend or build but I would really like to see what other people have found and look at other options. I will also spend some time looking at the whole reflow process and self-assembly as I think that’s where I can save some more cash.

What’s next – well I’ve made some extra boards that I’m going to sell off and will most certainly be making some more project so watch this space!